Book Binding: How to Ensure High-Quality Results

Understanding Book Binding Techniques for Optimal Results

Types of Book Binding: From Perfect to Spiral

The way books get bound really matters when creating something that looks good and stands the test of time. There's quite a few different approaches out there depending on what someone wants. Take perfect binding for instance, which glues pages together along the spine area using strong adhesives. This gives publications like magazines and paperbacks that polished finish everyone recognizes. Spiral binding works differently though. It lets pages flip open completely flat, so people love it for things like school notebooks and planning calendars where flipping through pages needs to be effortless. For smaller items like brochures or short booklets, saddle stitching is probably the go to method since it's quick and budget friendly. Then we have case binding, otherwise called hardcover binding, which makes books tough enough to survive generations of readers. Cookbooks and serious novels usually come in this format because they need extra protection against wear and tear. Industry stats show most commercial publishers still stick with perfect binding for mass produced works, whereas schools tend to gravitate toward spiral bound or saddle stitched products for their teaching materials.

The Role of Grain Direction in Binding Durability

The way paper grains are aligned makes all the difference when it comes to how long a book will last and how flexible its pages feel. Think about it this way: paper fibers run in certain directions, mostly going either along the spine or across from it. Binders who ignore these natural fiber directions often end up with problems down the road. Books tend to crack at the spine or warp out of shape if the grain isn't respected during binding. Some research backs this up too showing that getting the grain right means smoother page turns and fewer torn corners over time. For those making hardcover editions or doing perfect bound jobs, paying attention to grain direction isn't just nice to have but absolutely necessary for quality work. While matching the grain does cost a bit extra upfront, most publishers find that books last much longer in the hands of readers who appreciate well made products.

Case Binding vs. Mechanical Binding: Pros and Cons

Looking at durability, looks, and what they cost, case binding and mechanical binding each have their own strengths. Case binding stands out because it's really tough and looks great too. That's why publishers often go for it when creating those fancy textbooks or special edition books that need to last forever. But let's face it, this method costs a pretty penny and doesn't allow much flexibility once done. Mechanical binding works differently. Think about those spiral bound notebooks or wire bound manuals everyone loves flipping through. These bindings let pages turn smoothly and make updating content super simple. Great for things like training materials or field guides where people need access to information quickly. The downside? They just don't have that same refined appearance as case bound books do. Most print shops will tell anyone who asks that serious publishing houses stick with case binding for their premium products, whereas businesses looking for practical solutions without breaking the bank tend to opt for mechanical binding options.

Key Factors for High-Quality Book Binding

Choosing the Right Binding Glue: EVA vs. PUR

Picking the correct adhesive for bookbinding matters a lot if we want our books to last and look good. Most folks in the trade work with either Ethylene Vinyl Acetate (EVA) or Polyurethane Reactive (PUR). EVA is cheaper stuff that dries quickly, so it works well on those fast moving production lines where speed counts. But here's the catch: after some time passes, especially around heat sources, EVA just doesn't hold up as well as people would hope. On the flip side, PUR gives much better bonding power and stays flexible even after years of handling. That's why libraries tend to prefer it for their reference materials that get constant use. Sure, PUR costs more upfront, but it stands up against both temperature changes and chemical exposure, saving money down the road. The pros will usually point towards PUR whenever they need something that lasts. So when shopping for glue, think about what kind of life expectancy the finished product needs versus how much budget is available for materials.

Paper Selection and Thickness for Longevity

What kind of paper we pick really affects how long a bound book will last. When choosing between different types and thicknesses, the goal is simple: make sure the book looks nice while standing up to regular handling over years. Take heavier paper weights for example they offer extra strength, which makes them great choices for books people actually flip through a lot like textbooks or recipe collections. Most printers suggest going with something around 80 grams per square meter at minimum if we want our creations to hold together. Paper quality matters too when picking binding methods. Coated sheets tend to stick better during case binding because their surface is so smooth. People who take care in selecting the right materials usually end up happier with their finished products since good paper choices mean longer lasting books that look better on shelves and feel nicer in hands.

Design Considerations to Prevent Spine Damage

The way books are designed makes all the difference when it comes to protecting spines during binding. Things like gutter width (that space between page edges and the binding) and overall cover design matter a lot. When gutters are too narrow, important text or pictures just disappear into the fold, putting extra pressure on the spine over time. Good designers know to tweak their layouts based on what kind of binding method will be used, especially if there are lots of graphics involved. Text shouldn't line up exactly across spreads either since this creates weak points that break down faster. Most experienced bookmakers will tell anyone who asks that thinking about how pages will bind together right from the start saves headaches later on. Getting these details right upfront means readers won't end up with books that fall apart after a few months on the shelf.

Best Practices in Book Binding Production

Balancing Cost and Durability in Binding Methods

Finding the sweet spot between what it costs to produce books and how long they last remains a big headache for anyone involved in publishing. Getting this right means making smart choices about what materials go into each book and how efficiently things get made, so publishers end up with products that don't break the bank but still stand the test of time. For instance, many companies now opt for PUR glue even though it costs a bit more initially because it holds up better and offers more flexibility than cheaper alternatives. Streamlining operations matters too. Some shops have cut their expenses by tweaking when different tasks happen during production runs and investing in machinery that uses less electricity. According to folks who know the business inside out, these kinds of adjustments often lead to real improvements in bottom line numbers without sacrificing quality. The whole point here is that publishers need to keep innovating and thinking ahead if they want to stay profitable while keeping readers happy with durable books worth their money.

Print-on-Demand and Short-Run Binding Workflows

Print on demand services have really shaken up how books get bound traditionally, giving publishers options they never had before when it comes to flexibility and customizing what gets printed. With this new way of doing things, publishers can actually make books only when someone orders them, which cuts down on those huge storage costs and lets them react faster to what people want right now. For smaller operations and indie authors looking to get their work out there, short run binding makes a lot of sense economically while also cutting down on wasted paper and materials. But there are definitely some hurdles too, especially when production needs change quickly throughout the day. Look at companies such as Amazon and Lulu who've built entire businesses around this model. They show us just how powerful print on demand can be for responding to customers' specific requests and making sure everyone gets exactly what they need without all the overhead of mass production. The publishing world is clearly moving away from printing thousands of copies at once toward something much more responsive to actual reader demand.

Recommended Products for Professional Book Binding

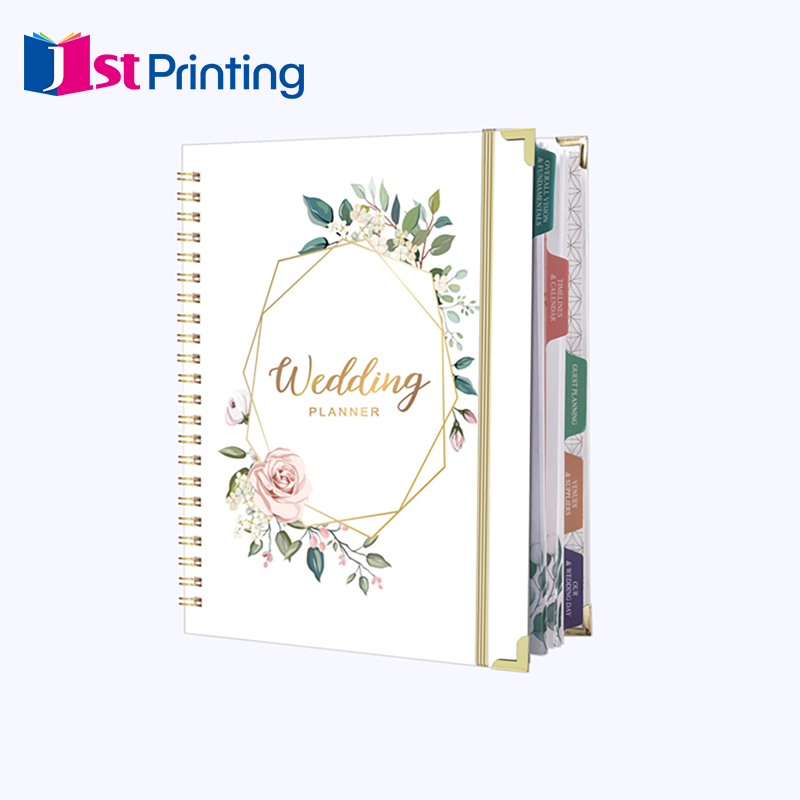

Custom Rose Gold Foil Spiral Organizer: Durable Mechanical Binding

The Custom Rose Gold Foil Spiral Organizer manages to combine lasting durability with attractive design features, making it great for mechanical binding tasks. What sets this planner apart is not just how good it looks, but also how well it works day after day. Made from thick, tear-resistant paper stock and featuring that eye-catching gold foil finish on the cover, it stands out on any desk. We're seeing more demand for these kinds of premium organizers lately, especially among professionals who want something that looks professional but still gets the job done. People who actually use them report staying organized longer because pages stay aligned better than cheaper alternatives, plus the gold accents just make their workspace feel more put together.

Waterproof Card Printing: Moisture-Resistant Material Binding

Waterproof card printing really holds up well against wear and tear plus all sorts of weather conditions, which makes it great for creating bindings that won't get damaged by moisture. The benefit becomes especially important when dealing with books or documents that might end up outside or somewhere damp. We've seen real world examples where products made with these water resistant materials lasted way longer than regular ones, even when faced with rain, humidity or accidental spills. For anyone looking at longevity in their printed materials, this kind of protection definitely pays off over time.

Wholesale Custom Oracle Cards: Precision-Cut Edge Binding

Making custom oracle cards requires some serious attention to detail, which is where precision cut edge binding really shines. The technique not only makes these special cards work better but also looks amazing when held in hand something that matters a lot as more people seek out personalized items these days. Looking at recent sales numbers shows just how big this market has gotten. Card makers are constantly coming up with new ways to bind their creations because customers want both unique designs and top notch quality. Some folks even collect different types of bindings now, treating them almost like art pieces rather than just tools for divination.